180-5843-6678

|

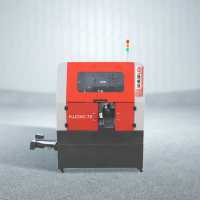

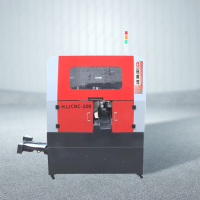

HJJCNC-200金属圆锯机

收藏

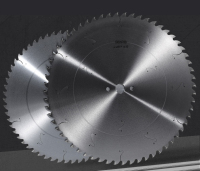

高速锯切提升效果( high speed sawing improve efficiency) 外径80mm中碳钢棒材,循环时间15-16秒(80mm outer diameter carbon steel bars,cycle time 15-16 seconds) 外径110mm中碳钢棒材,循环时间20秒(110mm outer diameter carbon steel bars,cycle time 20seconds) 外径150mm中碳钢棒材,循环时间33秒(150mm outer diameter carbon steel bars,cycle time 33seconds) 较数控带锯床切割工件较率提高5-10倍(5-10 times higher than efficiency CNC band sawing machine cutting ) 高精度的锯切精度 (High-precision cutting precision) 整体铸造机台底座+直线导轨导向,有效提高设备运行的平稳性、可靠性;(The casting mschine base+ linear Guide、improved stability,reliability of equipment;) 精密齿轮箱主轴传动+主轴稳定系统,提高锯切精度,降低锯片损耗;(precision gear box drive+spindle system ,improve the cutting precision and reduce blade loss; ) 自动送料、锯切进刀系统采用高性能伺服电机+高精度滚珠丝杆,确保送料、锯切精密传动无间隙。(Automatic feeding,cutting feed system using high performance servo motor+high-precision ball screw,ensure sending materials,sawn cut precision driving without gaps。) 经济、低成本运行(Economy,low running costs;) 圆锯片刀头采用进口金属陶瓷刀头,确保锯切精度及使用寿命;(Circlar saw blades used importde metals ceranic cutter head,ensure that the cutting precision and service life;) 选用进口喷雾润滑冷却系统,提高圆锯片使用寿命,降低锯切成本;(lmported spray lubrication and cooling systems,improve the circular saw blade service life,reduce cutting costs;) 设备运动部位采用自动润滑系统,减少设备运行磨损,提高设备使用期限;(Moving parts of equipment with automatic lubrication system,reduce equipment wear,and enhance the lifespan of equipment;) 一人控多机,有效降低人工成本,整体切割成本降低1/3-1/2。(A person controlled machine,reduces labor costs,total cost of cutting down 1/3-1/2.) 自动化控制系统 (Automation control system;) 采用最先进的CNC智能数据切削主控制系统和人性化软体界面相结合,互动式的触控屏幕操作简单;(Using the most advanced CNC cutting master of intelligent data systems combined with user-friendly software interface,interactive touch screen and easy operation) 先进的自动材料备料架,与主控系统配合,实现自动备料,无料直停机;(Advanced automatic material stock,with the master system,automatic feed preparation,feeding,without material downtime) 实现从备料到锯切全自动。(From preparation to the fully automatic sawing)

|